The construction industry in Florida is a significant and dynamic sector of the state’s economy. Florida’s construction industry benefits from a booming population, a strong tourism sector, and a constant demand for residential, commercial, and infrastructure development.

Florida, renowned for its thriving real estate market and iconic architectural styles, is currently undergoing a significant transformation in the construction sector. The integration of cutting-edge technologies, particularly 3D printing and modeling, is reshaping the way buildings and infrastructure are envisioned and built.

Blessed with picturesque beaches and lively urban centers, Florida has long been a focal point for construction endeavors. Nevertheless, the industry is standing at the threshold of a fresh era. The emergence of 3D printing technology, which has already left its mark in numerous industries, is steadily gaining traction within the Sunshine State.

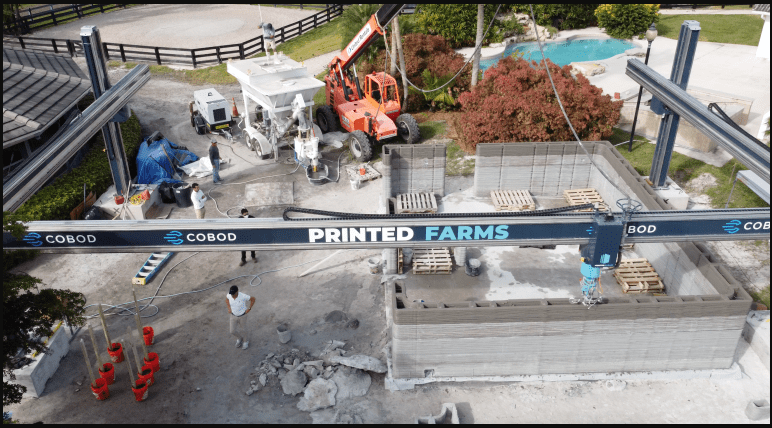

Florida’s Printed Farms creates history by printing the largest 3D-printed structure ever, a luxurious horse barn

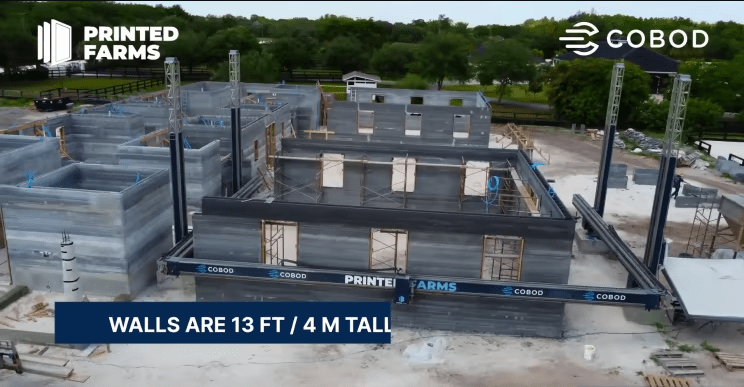

On June 8, 2023, Printed Farms, a Florida based construction company known for pioneering 3D printed structures, completed the world’s largest 3D printed building. They crafted the extraordinary structure using COBOD’s BOD2 construction 3D printer and hence set a new record for the world’s most widely used 3D printing technology.

This monumental project manifests the amazing capabilities of 3D printing technology in the construction industry. The luxurious horse barn has a total floor area of 10,100 square feet and makes it nearly 50% larger than the previous record holder in the Middle East. This impressive feat is designed to withstand extreme weather conditions that prevails in Florida. Florida, is a region which is known for tropical storms and hurricanes and the entire structure offers occupants safety.

COBOD is a known provider of construction 3D printers which has been used for crafting this groundbreaking project and has established itself as a leader in the industry. The BOD2 printer from the company is known for holding meaningful records for3D printed buildings which includes 33 feet/9.9 meters buildings in Saudi Arabia. This is the tallest building there. The printer is known for building the buildings at a fast pace and it has built 3 buildings in 8 days in Oman and now it has crafted the largest 3D printed building in the world.

The specs of the luxury horse barn are enthralling. It measures 13 feet in height, spans 155 feet in length and has a width of 83 feet approximately. The 3D printing process involves 5 passes of the printer where both sides are completed twice and the middle section is executed once.

A notable benefit of 3D printing technology manifested in this project is the creation of 3D printed walls with cavity and air gap. The innovative design offers natural cooling to the building and is energy efficient. Printed Farms has once again pushed the boundaries of 3D printing in construction and demonstrates the versatility and potential of technology to revolutionize the industry. This accomplishment confirms Florida’s status as a center for cutting-edge developments in construction technology.

To understand all the aspects of this groundbreaking project let’s understand what 3D printing is, and how it is used in construction?

What is 3D printing?

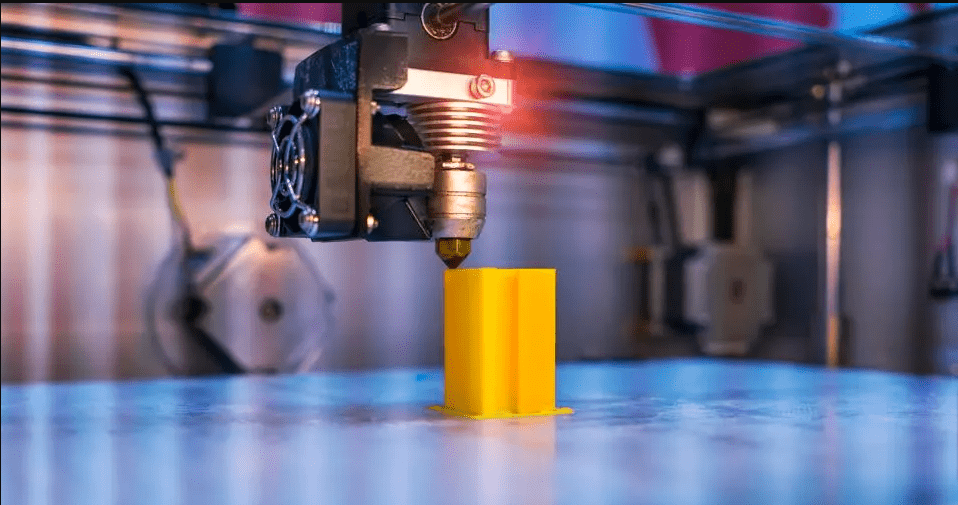

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file by layering material on top of itself. Unlike traditional subtractive manufacturing, where the material is cut away from a solid block, 3D printing builds objects layer by layer, which allows for the creation of complex and customized shapes.

Here’s how the process generally works:

a. Design:

First, a 3D model of the object to be printed is created using computer-aided design (CAD) software. This digital file serves as a blueprint for the 3D printer.

b. Printing:

The 3D printer reads the digital file and starts the printing process. The printer deposits material layer by layer, following the design specifications. Various types of materials can be used for 3D printing, including plastics, metals, ceramics, and even food substances.

c. Layering:

The printer creates each layer by solidifying or fusing the chosen material. This layering process continues until the entire object is formed.

d. Post-Processing:

After the printing is complete, the object might need some post-processing steps. This can include removing support structures, smoothing the surface, or painting to achieve the desired final result.

What are 3D models?

A 3D model is a digital representation of a three-dimensional object or scene. These models are created using computer-aided design (CAD) software or 3D modeling software and are typically used for various purposes, including visualization, simulation, animation, and 3D printing.

Listed below are some key aspects of 3D models:

a. Geometry

3D models consist of geometric shapes such as points, lines, curves, and surfaces that define the object’s structure. These shapes are often organized into a mesh of polygons (e.g., triangles or quads) to create the 3D surface.

b. Texture

In addition to geometry, 3D models can include texture information. Textures are 2D images applied to the surface of the 3D object to give it color, pattern, and detail.

c. Materials

3D models can be assigned various materials, each with its own properties such as color, reflectivity, transparency, and more. Materials affect how the object interacts with light and the visual appearance of the model.

d. Rigging and Animation

For animated 3D models, additional information may be added to enable movement and deformation. This includes skeletal rigging for characters and keyframe animations for objects and scenes.

What is a 3D building?

3D building typically refers to the process of creating a three-dimensional digital model of a building or architectural structure. This model can be used for various purposes, such as visualization, analysis, simulation, and virtual tours. 3D building models are created using specialized computer-aided design (CAD) software or Building Information Modeling (BIM) tools. Here are a few key aspects related to 3D building modeling:

a. Visualization:

3D building models provide a realistic and immersive way to visualize architectural designs. Architects and designers use 3D models to showcase their concepts to clients, stakeholders, and the public. These models can include details such as textures, colors, and lighting to enhance realism.

b. Design and Planning:

Architects and engineers use 3D building models to explore different design options and assess their feasibility. These models enable professionals to visualize the spatial relationships within a building and make informed decisions about layout, materials, and aesthetics.

c. Simulation and Analysis:

3D building models can be used for simulations and analyses, such as energy efficiency studies, lighting analysis, and structural simulations. Software tools can simulate how sunlight will enter the building at different times of the day or analyze the structural integrity of the design.

d. Construction and Project Management:

During the construction phase, 3D building models are valuable for project management. Construction teams can use these models for clash detection, construction sequencing, and coordination among different trades. BIM tools allow for collaboration and data sharing among project stakeholders.

3D printing used in construction:

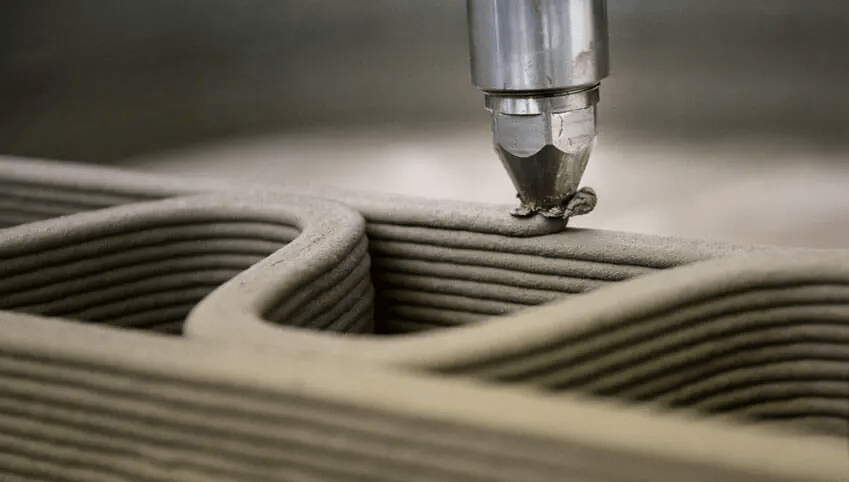

3D printing technology has found significant applications in the construction industry, transforming the way buildings and infrastructure are designed and constructed. This innovative approach, often referred to as “3D printing in construction” or “construction 3D printing,” utilizes large-scale 3D printers and specialized materials to create structures layer by layer.

Here are some key aspects of 3D printing in construction:

a. Speed and Efficiency:

3D printing allows for rapid construction compared to traditional methods. Large-scale 3D printers can build entire walls or even entire buildings in a fraction of the time it takes using conventional construction techniques.

b. Cost-Effectiveness:

While initial investments in 3D printing technology can be high, the overall cost of construction projects can be significantly reduced. This is especially true for large-scale projects where labor costs and construction time are major factors.

c. Design Flexibility:

3D printing enables architects and designers to create complex and innovative architectural designs that would be difficult or impossible to achieve with traditional construction methods. Unique shapes and intricate details can be easily incorporated into the design.

d. Reduced Material Waste:

Traditional construction methods often generate a lot of construction waste. 3D printing, on the other hand, is an additive process, meaning material is deposited only where it is needed. This reduces material waste substantially.

e. Customization:

3D printing allows for a high degree of customization. Builders can tailor construction elements to meet specific requirements, making it ideal for creating custom components for unique architectural designs.

f. Sustainability:

Many 3D Printing for Construction methods utilize eco-friendly materials, and the reduced material waste also contributes to environmental sustainability. Additionally, some construction 3D printing techniques incorporate recycled materials.

So, we can see that 3D Printing for Construction has significantly reduced construction cost and time that allows rapid deployment of housing in emergency situations. The low labor and material cost makes it the most ideal option for building different structures and that too beautifully. 3D printing offers intricate and customized designs which are challenging and expensive to achieve with traditional construction methods. Some 3D printing technologies also employ eco-friendly and recyclable materials which reduces material waste as well.

These homes and construction projects are gaining popularity as they have the potential to address housing shortages offering affordable housing solutions. Printed Farms has pushed the boundaries of 3D printing in construction once again and employed the technology to transform the industry. This remarkable achievement cements Florida’s position as a focal point for pioneering advancements in construction technology and it is a historic milestone in the world of 3D printed construction.