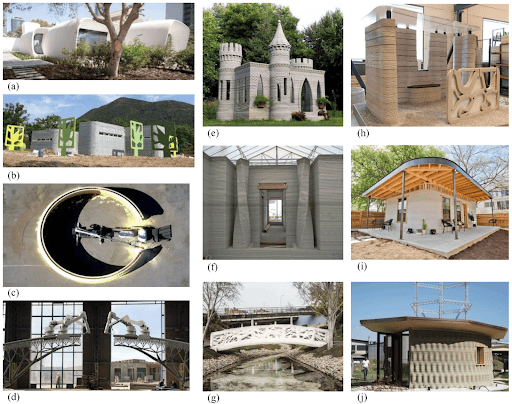

The construction industry is on the brink of a technological revolution, with 3D printing emerging as a transformative force. This innovative approach to construction has the potential to revolutionize how buildings and structures are designed and constructed. In this article, we will delve into the myriad advantages and challenges associated with the integration of 3D printing in construction industry.

Advantages of 3D Printing in Construction

a. Speed and Efficiency

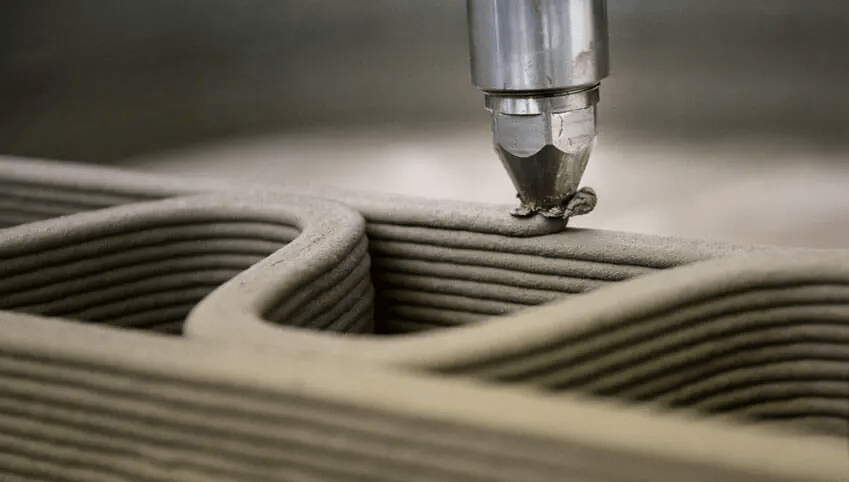

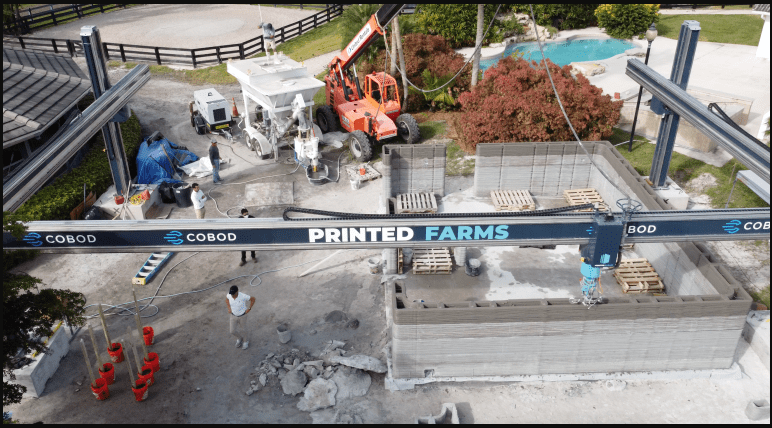

The primary benefits of 3D printing in the construction industry lie in its ability to expedite the building process. Bricklaying, concrete pouring, and other labour-intensive operations are all part of traditional construction procedures. Contrarily, 3D printing enables quick layering of building elements, drastically lowering construction time. When building quickly is necessary in an emergency, this speed can be extremely helpful.

Complex architectural plans that traditionally took a long time to implement using traditional techniques can now be done precisely and quickly. More ambitious and creative architectural ideas are now possible because of this improved efficiency.

b. Cost-Efficiency

The financial implications of 3D printing for construction are substantial. 3D printing can result in significant cost reductions by reducing material waste and maximizing resource use. The budget for a project may be significantly increased by the excessive material waste that frequently occurs in traditional construction. On the other hand, 3D printing uses only the material required for construction, minimizing waste and eventually saving expenses.

It is interesting how labor expenses have decreased as a result of 3D printing. While professional labor is still required to operate and maintain 3D printing equipment, there are fewer labor requirements overall when compared to conventional construction techniques.

c. Customization and Design Freedom

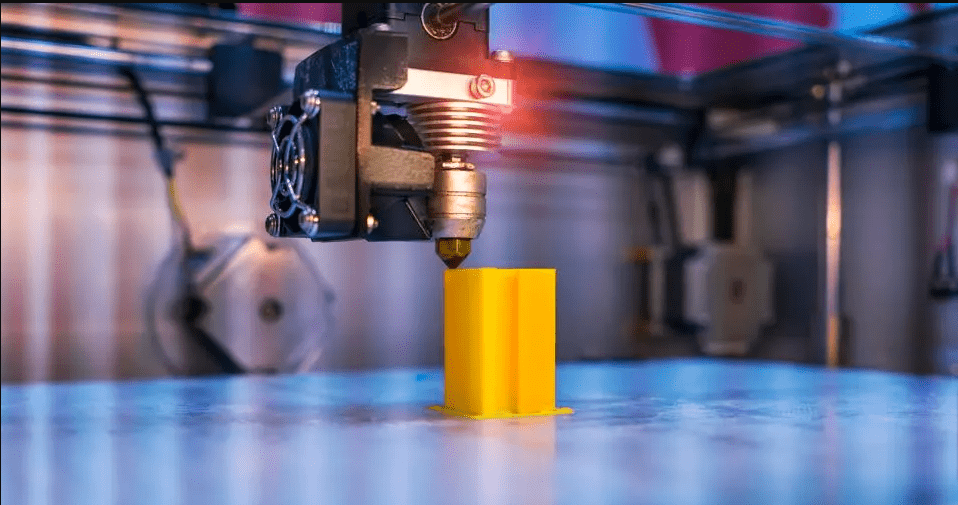

One of the most compelling advantages of 3D printing in the construction industry is its ability to facilitate unprecedented levels of customization and design freedom. Due to the constraints of conventional tools and materials, complex, organic, or intricately shaped designs are frequently difficult to realize using conventional building methods. These restrictions are overcome by 3D printing, enabling engineers and architects to realize their most ambitious designs.

This increased architectural freedom makes it possible to build structures that are not only useful but also aesthetically beautiful and visually appealing. There are now less limitations placed on architects by traditional building materials, which opens up a world of imaginative possibilities.

d. Sustainability

Modern construction methods must take sustainability into account, and 3D printing perfectly fits this attitude. Sustainable construction is significantly aided by the 3D printing phenomenon’s ability to reduce material waste. The environmental impact of construction projects is reduced by this method by utilizing only the essential amount of material.

The use of recycled and reused materials in 3D printing further lessens the environmental impact of construction projects. This focus on sustainability is advantageous for both the environment and the rising market for environmentally friendly building practices.

e. Safety and Reduced Risk

The use of 3D printing technologies can dramatically improve site security. It reduces the possibility of human error, which is a major contributor to accidents in conventional construction, by automating various construction procedures. Additionally, this automation lessens the necessity for employees to perform strenuous activities, potentially lowering the danger of accidents occurring on the job.

Structures are constructed precisely thanks to 3D printing technology, reducing the possibility of structural failures or flaws. This higher standard of quality assurance helps ensure the overall integrity and safety of the project.

Challenges and Limitations of 3D Printing in Construction

a. High Initial Investment

Although there are several long-term advantages to 3D printing in the building industry, there might be a significant upfront cost. It costs a lot of money upfront to buy and set up 3D printing equipment, as well as the required software and training. This can pose a challenge of 3D Printing and as a considerable barrier for smaller construction firms or projects with limited budgets.

To mitigate this challenge, industry stakeholders may need to explore collaborative models, such as partnerships with technology providers or shared access to 3D printing facilities.

b. Material Limitations

Although the range of printable construction materials is expanding, there are still limitations of 3D printing compared to the array of materials available in traditional construction. This may affect the adaptability and durability of 3D-printed structures. For instance, the use of 3D printing in particular construction environments may be constrained by the suitability of specific materials for load-bearing components.

To close this gap and improve the applicability of 3D printing for a wider range of construction projects, scientists and researchers are working hard to increase the variety of printable materials.

c. Regulatory Hurdles

To ensure the safety and compliance of structures, the construction sector is subject to strict rules and building codes. It might be quite difficult to modify these guidelines to take 3D printed structures into account. The lack of established procedures and regulations pertaining to 3D-Printed construction may be holding down the adoption of this technology at the moment.

There are initiatives underway to involve regulatory agencies, business organizations, and professionals in creating standardized procedures for 3D printing in the building industry. This cooperative method is essential for managing the regulatory environment.

d. Lack of Skilled Workforce

Equipment for 3D printing needs to be operated and maintained by people with specialized knowledge and abilities. It can take a long time and be expensive to train a workforce in these areas. In areas where the technology is still developing, there may also be a shortage of qualified experts with experience in 3D printing.

Investments in education and training programmes that provide people with the knowledge and abilities necessary to operate and maintain 3D printing equipment are required to address this challenge. In order to create a trained workforce, collaboration between educational institutions, business organizations, and technology providers might be crucial.

e. Scale and Size Restrictions

The size of buildings that can be created with current 3D printing technology is restricted. While it excels at creating minor to medium-sized components, it could be less appropriate for larger projects or projects in locations with limited space. Due to this restriction, a hybrid strategy that combines 3D printing and conventional construction techniques may be required to reach the requisite scale.

With the help of developments in printing, robotics, and materials science, researchers and engineers are actively investigating methods to scale up 3D printing capabilities.

Conclusion

How we conceptualize and realize architectural ideas has advanced significantly with the adoption of 3D printing in the construction sector. Numerous benefits include improved speed and effectiveness as well as unmatched design freedom and sustainability. The difficulties posed by this technology, such as the high initial costs of investment, material constraints, regulatory issues, worker training requirements, and scale limitations, must be acknowledged and addressed.

3D printing is positioned to play a significant role in the future of the construction industry as technology develops and industry players work together to address these issues. By utilizing the potential of this game-changing technology, we have the chance to reinvent the way we construct and design buildings that are not just practical and secure but also forward-thinking and sustainable. The possibilities are endless as we move closer to a 3D-printed future in construction.